What do electric vehicles, smartphones, and wind turbines all have in common? Rare earth elements (REEs)! Despite their name, rare earths are everywhere — at least in our high-tech gadgets. However, extracting them efficiently is like sorting out a very stubborn bowl of mixed marbles. Engineers have been working hard to crack this puzzle, so let's dive into the latest rare earth separation technologies that are helping us ensure a sustainable supply!

Table of Contents

What Are Rare Earth Separation Technologies?

Rare earth elements (REEs) represent a group of 17 metallic elements crucial to modern technological applications. Separating these elements is uniquely challenging due to their similar chemical properties and close atomic radii, which makes traditional separation techniques complex and resource-intensive.

The Critical Nature of REE Separation

REE separation is fundamental to numerous high-tech industries, including:

- Electronics manufacturing

- Renewable energy systems

- Advanced defense technologies

- Precision medical equipment

Solvent Extraction: Why Is It Still Widely Used?

Solvent extraction remains the primary method for REE separation, leveraging liquid-liquid extraction principles to isolate individual rare earth elements. This technique involves using organic solvents to selectively extract specific REEs from aqueous solutions.

Technical Mechanism

- Utilizes chemical differences between REEs

- Involves multiple extraction stages for increased purity

- Enables selective separation through carefully designed chemical interactions

Advantages and Limitations

Pros:

- High scalability

- Well-established technology

- Proven industrial application

Cons:

- Significant environmental impact

- Energy-intensive process

- Requires extensive chemical reagents

Ion Exchange: A Highly Selective Approach

Ion exchange processes offer remarkable precision in REE recovery by utilizing specialized resins that selectively capture and exchange ions based on their chemical properties.

Key Characteristics

- Employs synthetic or natural ion-exchange resins

- Enables separation of chemically similar REEs

- Particularly effective for elements like Neodymium and Dysprosium

Pros:

- Produces high-purity elemental outputs

- Allows precise chemical manipulation

Cons:

- Limited processing throughput

- High operational costs

- Complex resin regeneration processes

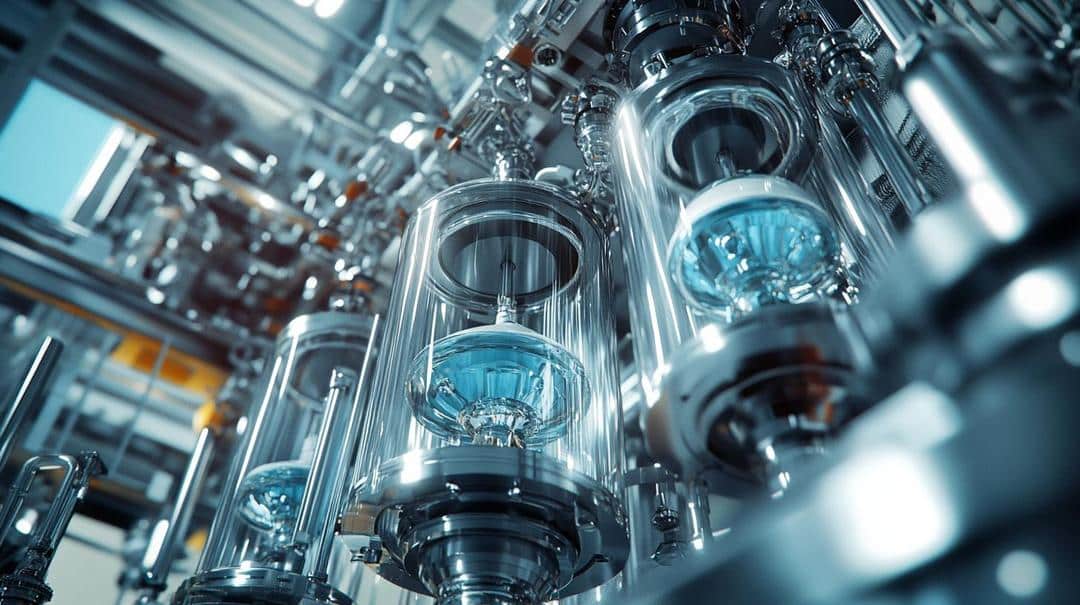

Membrane-Based Separation: The Future of Green Extraction?

Membrane technologies represent an emerging approach to REE separation, focusing on sustainable and environmentally friendly extraction methods.

Technological Innovations

- Polymeric and ceramic membrane development

- Reduced chemical consumption

- Lower energy requirements compared to traditional methods

Pros:

- Environmentally sustainable

- Minimal chemical waste generation

Cons:

- High membrane production costs

- Limited current industrial adoption

- Ongoing technological refinement needed

Electrochemical Separation: A High Precision Method

Electrochemical techniques leverage the unique electrical behaviors of rare earth elements to achieve precise separation and purification.

Separation Mechanisms

- Electrolytic refining processes

- Controlled electrical potential applications

- Targeted elemental deposition techniques

Pros:

- Low waste generation

- High-purity extraction potential

Cons:

- Significant capital investment requirements

- Limited applicability across all REEs

Magnetic Separation: How Simple Physics Can Help

Magnetic separation exploits the magnetic properties of certain rare earth mineral compounds to enhance extraction efficiency.

Technical Approach

- Utilizes high-gradient magnetic separators

- Focuses on magnetite-bearing mineral processing

- Incorporates advanced superconducting magnet technologies

Pros:

- Non-chemical separation method

- Simple operational principles

Cons:

- Requires significant preprocessing

- Limited to specific mineral compositions

Hybrid Methods: The Power of Combining Technologies

Emerging hybrid separation techniques combine multiple extraction methods to address complex rare earth element recovery challenges.

Strategic Combinations

- Integrating solvent extraction with membrane systems

- Combining ion exchange and electrochemical methods

- Tailored approaches for specific ore compositions

Pros:

- Customized solution development

- Enhanced overall extraction efficiency

Cons:

- Increased technological complexity

- Higher initial implementation costs

Conclusion

Innovations in rare earth separation technologies are driving industries forward, facilitating cleaner energy and more advanced electronics. From solvent extraction's well-established platform to cutting-edge membrane and hybrid technologies aiming for greener processes, the future of rare earth recovery looks promising. Professionals in chemical engineering, geology, and mining play a pivotal role in optimizing these essential techniques.

FAQs

What are rare earth elements and why are they important?

Rare earth elements (REEs) are a group of 17 chemical elements critical in manufacturing high-tech devices such as smartphones, wind turbines, and electric vehicles due to their unique magnetic, luminescent, and electrochemical properties.

Why is it challenging to separate rare earth elements?

Separating REEs is difficult because these elements have very similar chemical properties, making them hard to isolate from one another using standard chemical techniques.

What is the most commonly used rare earth separation technology?

Solvent extraction remains the most widely used rare earth separation technology, particularly because it can handle large volumes and provide high selectivity, even though it is energy-intensive and poses environmental challenges.

Is membrane-based technology a viable alternative for rare earth separation?

Yes, membrane-based technologies are showing promise as a more environmentally friendly and less chemically intensive alternative. However, challenges in cost and adoption still exist.

How do hybrid techniques enhance rare earth separation?

Hybrid methods integrate multiple technologies to achieve more efficient separation processes, overcoming the limitations of individual techniques and tailoring solutions for more complex ores.