Rare Earth Element

Scandium

Symbol: Sc

Ordinal Number: 21

Density: 2.99 g/cm³

Melting Point: 1,541°C (2,806°F)

Boiling Temperature: 2,836°C (5,137°F)

AI Representation

Introduction

Scandium: The Lightweight Champion in Aerospace and Sports Equipment

Scandium is a rare earth element known for its impressive strength-to-weight ratio, corrosion resistance, and thermal stability. Though not as abundant or commonly used as other metals, Scandium’s unique properties make it invaluable in high-performance materials, especially in the aerospace and sporting goods industries. When alloyed with aluminum, Scandium significantly enhances strength and durability without adding weight, making it ideal for applications where lightweight yet strong materials are essential. From advanced aircraft components to high-performance sports equipment, Scandium’s contributions to material science highlight its importance in modern technology.

History/Discovery

The Discovery of Scandium: Bridging Gaps in the Periodic Table

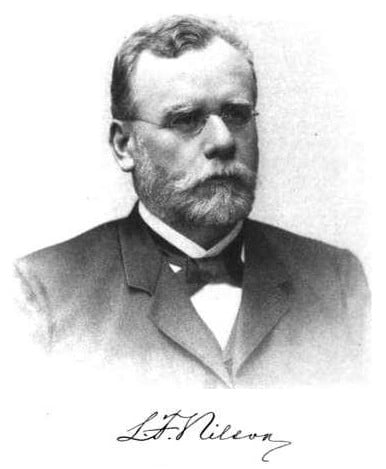

Scandium was discovered in 1879 by Swedish chemist Lars Fredrik Nilson, who identified it in the mineral euxenite. The element was named after Scandinavia, where the mineral was found. Interestingly, Dmitri Mendeleev had predicted the existence of an element with similar properties years earlier, calling it “eka-boron.” Scandium remained largely unused until the 20th century, when scientists recognized its benefits in strengthening aluminum alloys. Today, Scandium is primarily used in applications that demand lightweight, durable materials, particularly in industries focused on fuel efficiency and high-performance designs.

Characteristics

Scandium’s Distinctive Traits: Lightweight Strength and Corrosion Resistance

Samarium is a silvery, relatively hard metal that stands out for its stability in high-temperature environments. Its unique ability to resist demagnetization at elevated temperatures has made it a preferred material in manufacturing powerful magnets used in electric motors, aerospace equipment, and other high-stress applications. Samarium compounds also play an important role in nuclear technology due to their ability to absorb neutrons, contributing to radiation shielding and nuclear safety. Samarium’s high oxidation resistance further enhances its performance in applications requiring long-term durability, particularly where exposure to air and moisture is inevitable.

Popular Applications

Scandium’s Essential Role in Aerospace, Sports, and Green Technology

Scandium is a silvery-white metal known for its low density, high melting point, and impressive ability to resist corrosion. These traits make it particularly suitable for aerospace and sports equipment, where durability and weight reduction are critical. When alloyed with aluminum, Scandium increases the strength and reduces the grain size of the metal, resulting in improved weldability and structural stability. Additionally, Scandium has high thermal stability, allowing it to withstand extreme temperatures without losing its strength. These properties make Scandium an ideal material for applications requiring a combination of lightweight strength and resilience.

List of Popular Applications

- Aerospace Components: Scandium-aluminum alloys are used in aircraft parts, reducing weight and enhancing fuel efficiency.

- Sports Equipment: Scandium-alloyed materials are used in lightweight, high-strength sports gear, such as bicycle frames, baseball bats, and golf clubs.

- Solid Oxide Fuel Cells: Scandium improves the performance of fuel cells, making them more efficient and durable, supporting clean energy solutions.

- Automotive Industry: Scandium is being explored in automotive components to create lighter, more fuel-efficient vehicles with strong structural integrity.

Where You Find Scandium in the World

Global Production and Distribution of Scandium

Scandium is one of the least abundant rare earth elements and is primarily obtained as a byproduct of mining other minerals, such as uranium and rare earth ores. The largest sources of Scandium are in China, Kazakhstan, and Russia, with additional deposits in Australia and the United States. Due to its scarcity and high extraction costs, Scandium is considered one of the most expensive elements. As demand grows for lightweight alloys and fuel cell technology, securing sustainable sources of Scandium has become a priority for industries reliant on high-performance materials.

The Future of Scandium

Expanding Applications in Aerospace, Automotive, and Renewable Energy

With the push towards fuel efficiency and clean energy, Scandium’s role in advanced materials is expected to grow. Its use in aerospace and automotive applications is anticipated to increase as industries seek ways to reduce vehicle weight and improve fuel economy. In green technology, Scandium’s potential in solid oxide fuel cells holds promise for supporting renewable energy solutions. Sustainable extraction and recycling methods are being explored to meet future demand, allowing Scandium to continue supporting advancements in aerospace, automotive, and energy industries.