Rare earth elements are the unsung heroes of our modern world, powering everything from wind turbines to electric vehicles. But how do we get our hands on these crucial resources?

These elements are more common than their name implies, but the efforts to mine and refine them is nothing short of a challenge. And we haven’t even talked about the geopolitical dynamics or recycling hurdles to make it easier.

Let’s dig in!

What Exactly Is a Rare Earth Mining Guide?

Rare earth mining is the process of extracting and processing a group of 17 elements known as rare earth elements (REEs). Despite their name, these elements are not particularly rare in the Earth’s crust, but they are typically found in low concentrations, making their extraction challenging and often economically complex.

Rare earth elements include:

- Lanthanides (15 elements)

- Scandium

- Yttrium

Unique properties of REEs:

- Strong magnetic properties

- Luminescence

- Catalytic abilities

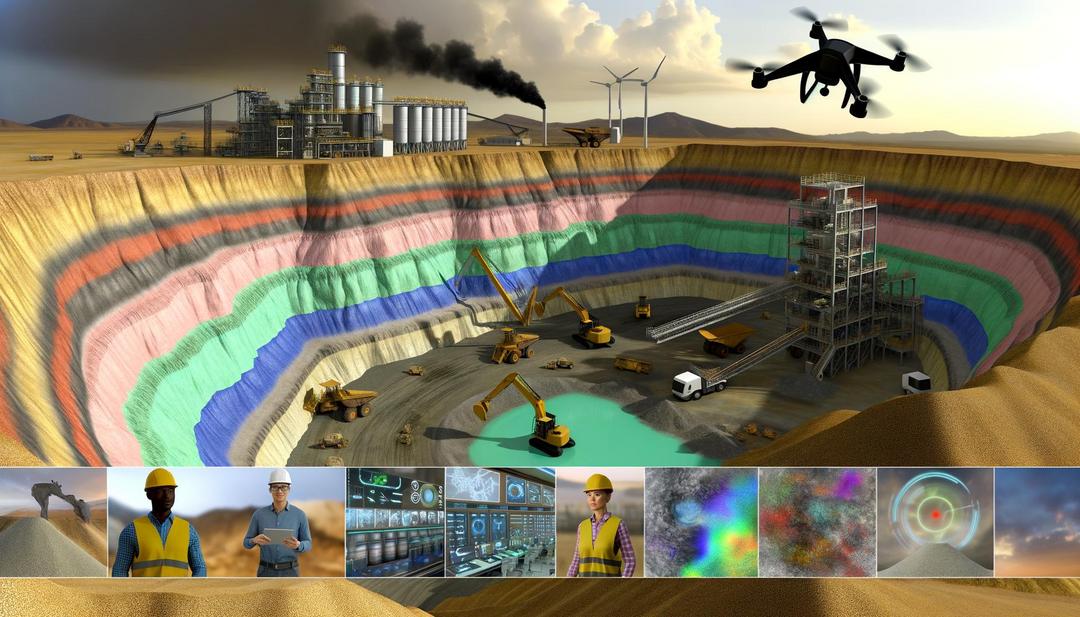

The rare earth mining process involves several stages:

- Exploration and discovery of deposits

- Extraction through open-pit or underground mining

- Beneficiation to concentrate the ore

- Separation of individual rare earth elements

- Refining and purification

Historical Context and Evolution

Rare earth mining has evolved significantly since the discovery of these elements in the late 18th century:

- 1787: First rare earth element (yttrium) discovered in Sweden

- 1940s-1950s: Development of ion-exchange technology for separating REEs

- 1960s-1970s: Mountain Pass mine in California becomes the world’s largest REE producer

- 1980s-present: China emerges as the dominant global supplier

Today, rare earth elements play a crucial role in modern technology and industry:

- Consumer electronics (smartphones, laptops)

- Renewable energy technologies (wind turbines, solar panels)

- Defense systems (guidance systems, night-vision goggles)

- Medical equipment (MRI machines)

- Automotive industry (electric vehicles, catalytic converters)

The Global Landscape of Rare Earth Mining

The rare earth mining industry is characterized by a complex global landscape, with production concentrated in a few key regions:

Major Rare Earth Mining Locations

- China: Produces over 80% of the world’s rare earth elements

- United States: Mountain Pass mine in California

- Australia: Mount Weld mine

- Myanmar: Significant producer, particularly of heavy rare earth elements

- Brazil: Substantial reserves, increasing production

China’s Dominance and Implications

China’s control over the rare earth market has significant implications:

- Supply chain vulnerabilities for other countries

- Potential for market manipulation and export restrictions

- Geopolitical leverage in trade negotiations

Emerging Players

Several countries are working to develop their rare earth mining capabilities:

- Canada: Exploring deposits in Quebec and Northwest Territories

- Greenland: Large-scale projects under development

- India: Increasing production and processing capabilities

- Vietnam: Collaborating with Japanese firms to develop resources

Geopolitical Tensions and Trade Disputes

The strategic importance of rare earth elements has led to various geopolitical issues:

- U.S.-China trade tensions impacting rare earth supplies

- Efforts by countries to secure their own rare earth supply chains

- International collaborations to counter China’s market dominance

Environmental Impacts: The Dark Side of Rare Earth Mining

Rare earth mining can have significant environmental consequences:

Ecological Consequences

- Habitat destruction and biodiversity loss

- Deforestation and soil erosion

- Alteration of local ecosystems

Water and Soil Pollution

- Acid mine drainage contaminating groundwater

- Release of toxic chemicals and heavy metals

- Long-term soil contamination affecting agriculture

Radioactive Waste Management

Many rare earth deposits contain naturally occurring radioactive materials:

- Thorium and uranium often present in rare earth ores

- Challenges in safely storing and disposing of radioactive waste

- Potential for long-term environmental and health impacts

Sustainable Mining Practices

Efforts to mitigate environmental impacts include:

- Implementation of closed-loop water systems

- Dry processing techniques to reduce water usage

- Rehabilitation and restoration of mined areas

- Development of bio-mining techniques using bacteria

Economic Significance: Why Rare Earth Mining Matters

The rare earth mining industry plays a crucial role in the global economy:

Role in Various Industries

- Aerospace and defense

- Clean energy technologies

- Advanced manufacturing

- Information technology and communications

Market Trends and Demand Projections

- Growing demand driven by technological advancements

- Projected market value of $9.6 billion by 2026

- Increasing focus on heavy rare earth elements

Economic Benefits and Challenges

Benefits:

- Job creation in mining and related industries

- Economic diversification for resource-rich countries

- Potential for value-added processing and manufacturing

Challenges:

- Price volatility due to supply constraints

- High capital costs for mine development

- Competition from recycling and alternative materials

Investment Opportunities and Risks

- Growing interest from investors in rare earth mining companies

- Risks associated with market concentration and geopolitical factors

- Potential for high returns but also significant volatility

Innovative Technologies Shaping the Future of Rare Earth Mining

Advancements in technology are transforming the rare earth mining industry:

Extraction and Processing Techniques

- In-situ leaching methods for reduced environmental impact

- Advanced separation technologies using solvent extraction

- Microwave-assisted extraction for improved efficiency

Recycling and Urban Mining

- Development of processes to recover REEs from electronic waste

- Urban mining initiatives targeting landfills and industrial byproducts

- Challenges in economically viable recycling at scale

Alternative Sources

- Exploration of deep-sea mining for rare earth-rich nodules

- Investigation of coal ash and other industrial waste streams

- Research into extracting REEs from phosphate rock processing

AI and Automation in Mining

- Use of machine learning for optimizing extraction processes

- Autonomous vehicles and robotics in mining operations

- Predictive maintenance to improve equipment efficiency

Sustainability Efforts in Rare Earth Mining

The industry is increasingly focusing on sustainable practices:

Green Mining Practices

- Energy-efficient processing technologies

- Water conservation and recycling systems

- Minimization of chemical use in extraction

Regulatory Frameworks and Standards

- Development of international standards for responsible mining

- Implementation of stricter environmental regulations

- Certification schemes for sustainably sourced rare earths

Case Studies of Sustainable Projects

- Lynas Corporation’s Advanced Materials Plant in Malaysia (opens in a new tab)

- Pensana’s planned rare earth processing facility in the UK (opens in a new tab)

- Mkango Resources’ Songwe Hill project in Malawi (opens in a new tab)

Circular Economy Approach

- Design for recyclability in rare earth-containing products

- Development of closed-loop supply chains

- Emphasis on resource efficiency and waste reduction

The Road Ahead: Challenges and Opportunities in Rare Earth Mining

The future of rare earth mining presents both challenges and opportunities:

Addressing Supply Chain Vulnerabilities

- Efforts to diversify global rare earth production

- Development of strategic reserves by various countries

- Investments in domestic processing capabilities

Balancing Growth and Environmental Protection

- Implementation of stricter environmental standards

- Research into remediation techniques for legacy mining sites

- Exploration of bio-based extraction methods

Impact on Renewable Energy Transitions

- Critical role of REEs in wind turbines and electric vehicles

- Potential supply constraints affecting clean energy goals

- Opportunities for integrating sustainability in both mining and end-use sectors

Emerging Research and Development

- Search for rare earth alternatives in certain applications

- Development of new magnetic materials with reduced REE content

- Advances in nanotechnology for more efficient use of REEs

Conclusion

From the environmental challenges to the economic opportunities, rare earth mining is a complex and fascinating field that will continue to shape our future.

As we move towards a more sustainable and technologically advanced future, the rare earth mining industry will undoubtedly play a pivotal role.

FAQs

What are the most common rare earth elements mined today?

The most commonly mined rare earth elements include neodymium, praseodymium, dysprosium, and terbium. These are crucial for manufacturing magnets used in various technologies, from smartphones to electric vehicles.

How does rare earth mining impact local communities?

Rare earth mining can have both positive and negative impacts on local communities. While it can provide jobs and economic opportunities, it may also lead to environmental degradation, health issues, and displacement of residents if not managed responsibly.

Is rare earth mining more harmful to the environment than other types of mining?

Rare earth mining can be more environmentally damaging due to the chemicals used in the extraction process and the potential for radioactive waste. However, advancements in sustainable mining practices are helping to mitigate these impacts.

Can rare earth elements be recycled?

Yes, rare earth elements can be recycled, although the process is complex and often expensive. Urban mining, which involves recovering rare earth elements from discarded electronics, is becoming an increasingly important source of these materials.

What are some alternatives to rare earth elements being developed?

Researchers are exploring alternatives such as iron-based magnets, synthetic materials, and nanotechnology solutions to reduce dependence on rare earth elements. However, many of these alternatives are still in early development stages.

Dustin

Driven by a fascination with rare earth elements and their role in powering modern tech and engineering marvels. A true car and tech enthusiast, he loves exploring how these hidden heroes fuel our most exciting innovations.

You Might Also Like…