Demand for rare earth elements certainly is skyrocketing. In fact, the global demand for neodymium, a key ingredient in EV motors, is projected to rise by over 70% by 2030, according to the International Energy Agency (IEA). As the electric vehicle (EV) revolution accelerates, understanding the implications of rare earth demand has never been more critical—or more complex.

Let's get into it.

Table of Contents

What Is EV Rare Earth Demand and Why Is It Growing?

Rare earth elements (REEs) are a group of metallic elements critical to modern technology, especially electric vehicles (EVs). These special metals play a crucial role in creating powerful and efficient electric motors and other key EV components. Among the most important REEs for EVs are neodymium, praseodymium, dysprosium, and terbium.

The Heart of Electric Motors

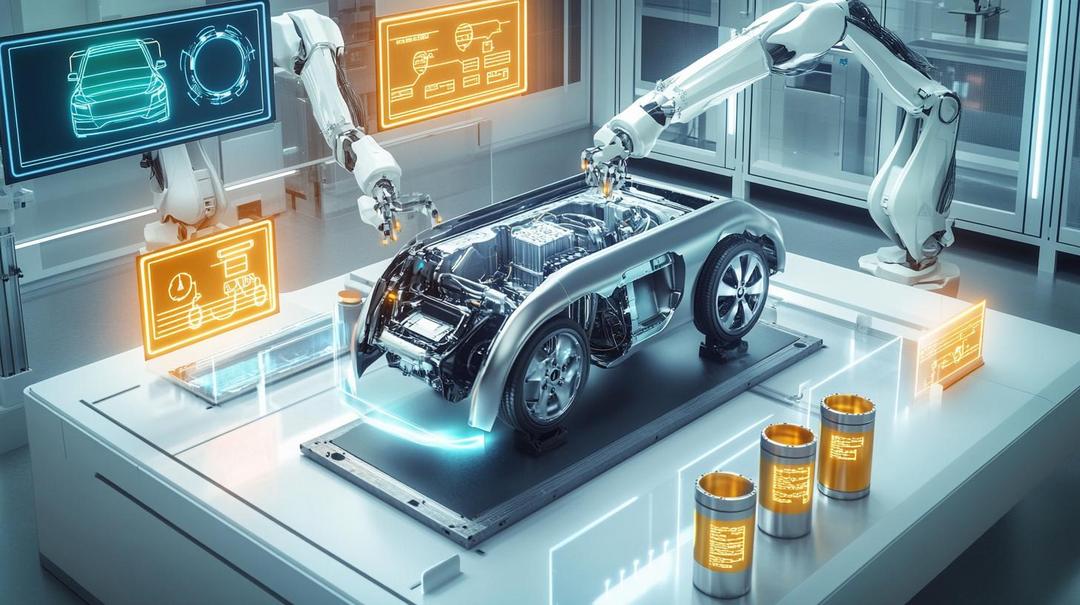

Electric vehicles rely on rare earth elements to create high-performance permanent magnet synchronous motors (PMSMs). These motors use special magnetic materials that allow for more compact, efficient, and powerful drivetrain systems compared to traditional internal combustion engines. Neodymium and praseodymium are particularly important, forming the core of these advanced motor technologies.

The global demand for rare earth elements in EVs is skyrocketing. According to the International Energy Agency (IEA), the EV market is expanding rapidly, driving unprecedented demand for these critical materials. Government policies, such as the Inflation Reduction Act in the United States and the EU Critical Raw Materials Act, are further accelerating this trend by supporting EV adoption and domestic supply chain development.

Critical Rare Earth Elements Powering EVs

Neodymium and Praseodymium: Motor Magnets

Neodymium-praseodymium (NdPr) alloys are the backbone of modern electric vehicle motors. These elements create powerful permanent magnets that enable high-efficiency electric drivetrains. They allow manufacturers to design smaller, lighter, and more powerful electric motors that can deliver impressive performance.

High-Temperature Performance Boosters

Dysprosium and terbium play a critical role in enhancing motor performance, especially in high-temperature applications. These elements help maintain magnetic properties at elevated temperatures, which is crucial for electric vehicles operating in diverse environmental conditions.

Battery and Fuel Cell Contributions

Rare earth elements extend beyond motors. Cerium and lanthanum are important in developing advanced battery technologies and fuel cell systems. Their unique chemical properties contribute to improved energy storage and conversion capabilities.

Forecasting Rare Earth Demand Through 2035

The future of rare earth elements looks incredibly promising. Projections from the IEA and Adamas Intelligence suggest dramatic increases in demand across different vehicle types. Battery electric vehicles (BEVs), plug-in hybrid electric vehicles (PHEVs), and hybrid electric vehicles (HEVs) will all drive this growth.

Under accelerated adoption scenarios, rare earth element demand could increase by several hundred percent by 2035. These projections account for improving technologies, falling battery costs, and aggressive government policies supporting electric transportation.

Impact of EV Market Growth on Global Supply Chains

Sourcing Challenges

The rare earth element supply chain is currently concentrated in China, creating significant geopolitical risks. Countries like the United States, Australia, and Canada are working to diversify supply chains and reduce dependency on a single source.

Recycling and Innovation

Urban mining and recycling technologies are emerging as critical strategies to address supply constraints. Automakers are exploring innovative approaches to secure materials, including long-term contracts and vertical integration of supply chains.

Environmental and Social Considerations in Rare Earth Mining

Rare earth element extraction comes with significant environmental challenges. Traditional mining processes can create substantial environmental impacts, including water pollution and radioactive waste. The industry is increasingly focusing on responsible sourcing and reducing ecological footprints.

Sustainable Extraction

Emerging technologies and stricter regulations are pushing the rare earth industry toward more sustainable practices. Companies are investing in cleaner extraction methods and working to minimize environmental and social impacts.

Innovations in Materials to Reduce Rare Earth Dependency

Researchers and manufacturers are developing alternative technologies to reduce rare earth element dependency. This includes:

- Advanced magnet technologies using fewer rare earth elements

- Motor redesigns that minimize REE requirements

- Solid-state battery innovations

- AI-assisted design for material efficiency

Strategic Policy Responses and Market Opportunities

Governments worldwide are implementing strategic policies to support rare earth element development. The U.S. CHIPS and Science Act, EU Green Deal, and Australia's Critical Minerals Strategy are creating new opportunities for domestic production and technological innovation.

Investment in mining, refining, and advanced manufacturing is accelerating, potentially reshaping the global rare earth element landscape in the coming decades.

Conclusion

Rare earth elements may only make up small portions of an EV's mass, but they're major drivers of its performance—and the EV industry's trajectory. From neodymium-powered motors to dysprosium-enhanced endurance, the future of mobility runs through the periodic table.

Understanding EV rare earth demand isn't just a concern for industry insiders—it's a question of industrial strategy, national security, sustainability, and innovation. With demand forecasted to outstrip supply in just a few years, stakeholders from policymakers to entrepreneurs must act now to build smarter, cleaner, and more resilient supply networks.

Interested in talking more about EVs and what is going on in the industry? Join one of our Forum Discussions (opens in a new tab).

FAQs

Why are rare earth elements essential in electric vehicles?

Rare earth elements like neodymium and dysprosium are critical for making high-performance permanent magnets used in electric motors. These magnets improve efficiency and power density in EV drivetrains.

Which EV components use the most rare earth materials?

The permanent magnet synchronous motor (PMSM) consumes the highest quantity of REEs. Other components like sensors and power electronics may also use REEs in smaller quantities.

Are there environmental concerns with rare earth mining?

Yes. REE extraction often involves toxic chemicals, extensive water use, and radioactive byproducts. Environmental regulations aim to mitigate these issues, and recycling is being developed as a cleaner alternative.

Is China the only major supplier of rare earths for EVs?

Currently, China dominates both the mining and refining of REEs. However, other countries like the U.S., Australia, and Canada are scaling up domestic production to reduce dependency.

Could future EVs avoid using rare earths altogether?

Emerging technologies may reduce or eliminate REE use, such as ferrite magnet motors and induction motors. However, high-performance EVs will likely continue to rely on REEs in the near term.