Traditional mining methods can be environmentally destructive. Enter in-situ leaching – a game-changing technique that's turning the rare earth mining world on its head! In this article, we are going to dive deep into in-situ leaching for rare earth elements.

Table of Contents

What Exactly is In-Situ Leaching Rare Earth Elements?

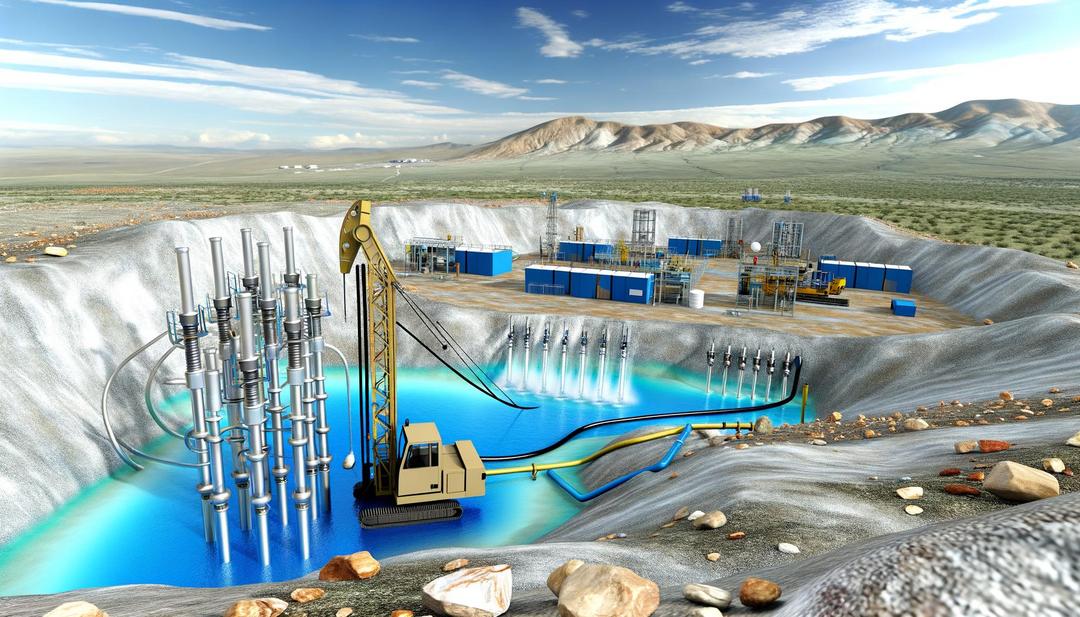

In-situ leaching, also known as in-situ recovery or solution mining (opens in a new tab), is a method of extracting valuable minerals like rare earth elements directly from the ground without traditional mining techniques. Here's what you need to know:

- It's like making a cup of tea, but underground! We dissolve the minerals we want using special solutions and then pump them back up to the surface.

- This method is way less disruptive than conventional mining – no huge open pits or underground tunnels.

- In-situ leaching has been around since the 1960s, but it's gaining more attention now for rare earth elements due to its potential environmental and economic benefits.

Compared to traditional mining methods, in-situ leaching is:

- Less invasive to the landscape

- Often more cost-effective

- Potentially more environmentally friendly (though this can vary depending on the specific project)

The Science Behind In-Situ Leaching: How Does it Work?

Now, let's get into the nitty-gritty of how in-situ leaching actually works. Don't worry, we'll keep it simple and fun!

The Step-by-Step Process

- Identify the deposit: Geologists locate a suitable rare earth element deposit underground.

- Drill baby, drill: Wells are drilled into the deposit – some for injecting the leaching solution, others for extracting it.

- Mix the magic potion: A special leaching solution is prepared, usually containing water and specific chemicals.

- Down the hatch: The solution is pumped down into the deposit through injection wells.

- Nature does its thing: The solution dissolves the rare earth elements from the surrounding rock.

- Pump it up: The mineral-rich solution is pumped back to the surface through extraction wells.

- Separate and purify: The rare earth elements are separated from the solution and purified.

The Chemistry Behind the Magic

- The leaching solution typically contains acids or other chemicals that can selectively dissolve rare earth elements.

- Different rare earth elements may require different chemical cocktails for optimal extraction.

- The process relies on the natural permeability of the rock to allow the solution to flow through and interact with the minerals.

Key Equipment and Technologies

- Drilling rigs for creating the injection and extraction wells

- Pumps for moving the leaching solution and mineral-rich fluids

- Monitoring systems to track the flow and chemistry of the solutions

- Processing plants to separate and purify the extracted rare earth elements

Environmental Impact: Is In-Situ Leaching a Greener Alternative?

When it comes to mining, environmental concerns are always at the forefront. So, how does in-situ leaching stack up against conventional mining methods? Let's take a look:

Comparing Footprints

- Less surface disturbance: In-situ leaching doesn't require large open pits or underground tunnels.

- Reduced waste rock: There's no need to dig up and store massive amounts of waste rock.

- Lower energy consumption: The process generally requires less heavy machinery and transportation.

- Water usage: While in-situ leaching does use water, it can often be recycled and reused in the process.

Potential Risks and Mitigation Strategies

- Groundwater contamination: This is the biggest concern. Proper well construction and constant monitoring are crucial.

- Solution containment: Ensuring the leaching solution stays within the target area is essential.

- Site restoration: After mining, the area needs to be carefully restored to its natural state.

Success Stories

- Several uranium mining operations have successfully used in-situ leaching with minimal environmental impact.

- Some copper mines have also adopted this technique, showing promising results in reducing their environmental footprint.

Remember, while in-situ leaching has the potential to be more environmentally friendly, each site is unique and requires careful planning and management to ensure responsible operations.

Economic Advantages of In-Situ Leaching for Rare Earth Elements

Now, let's talk money! In-situ leaching can offer some significant economic benefits compared to traditional mining methods. Here's why it might be a smart choice for rare earth element extraction:

Cost-Benefit Analysis

- Lower upfront costs: No need for expensive earthmoving equipment or underground mine development.

- Reduced labor costs: Fewer workers are required on-site compared to conventional mining.

- Faster time to production: In-situ leaching operations can often be set up more quickly than traditional mines.

Infrastructure Savings

- Minimal surface facilities: Most of the action happens underground, so you don't need as much infrastructure on the surface.

- Smaller footprint: This can mean lower land acquisition and reclamation costs.

- Less waste management: With little to no waste rock or tailings, you save on storage and treatment costs.

Unlocking New Opportunities

- Access to lower-grade deposits: In-situ leaching can make it economically viable to extract rare earth elements from deposits that would be too costly to mine conventionally.

- Reaching difficult locations: Some deposits that are too deep or in challenging terrain for traditional mining might be accessible through in-situ leaching.

Challenges and Limitations of In-Situ Leaching

While in-situ leaching sounds great, it's not a one-size-fits-all solution. Let's look at some of the challenges and limitations:

Geological Constraints

- Rock permeability: The deposit needs to be porous enough for the leaching solution to flow through effectively.

- Deposit type: Not all rare earth element deposits are suitable for in-situ leaching.

- Depth and size: The deposit needs to be at a suitable depth and large enough to justify the investment.

Technological Hurdles

- Solution chemistry: Developing the right leaching solution for specific rare earth elements can be complex.

- Flow control: Ensuring the leaching solution reaches all parts of the deposit evenly can be challenging.

- Recovery rates: In some cases, in-situ leaching may not recover as high a percentage of the minerals as traditional mining.

Regulatory and Permitting Issues

- Environmental concerns: Regulators may have strict requirements to prevent groundwater contamination.

- New territory: In some areas, regulations for in-situ leaching of rare earth elements may not be well-established.

- Public perception: Local communities might be hesitant about a new mining technique in their area.

The Future of Rare Earth Mining: In-Situ Leaching's Role

As we look to the future, in-situ leaching could play a significant role in meeting the growing demand for rare earth elements. Here's what we might expect:

Emerging Trends and Innovations

- Improved leaching solutions: Research is ongoing to develop more efficient and environmentally friendly leaching chemicals.

- Better monitoring technology: Advanced sensors and real-time data analysis could improve process control and environmental protection.

- Automation and AI: These technologies could optimize the leaching process and increase efficiency.

Impact on Global Supply

- Diversification of sources: In-situ leaching could help tap into new rare earth element deposits around the world.

- Reduced reliance on traditional mining: As the technology improves, we might see a shift away from conventional open-pit and underground mining for rare earth elements.

- Potential price stabilization: Increased supply and lower production costs could help stabilize rare earth element prices.

Integration with Other Technologies

- Combining with bio-leaching: Some researchers are exploring the use of bacteria to assist in the leaching process.

- Pairing with renewable energy: Solar or wind power could be used to run in-situ leaching operations, further reducing their environmental impact.

- Recycling integration: In-situ leaching techniques might be adapted to help extract rare earth elements from electronic waste or other recycled materials.

Conclusion

As we've explored, in-situ leaching for rare earth elements is not just a passing fad – it's a revolutionary approach that's reshaping the mining landscape. From its environmental benefits to its economic advantages, this technique offers a promising solution to our growing demand for these critical materials. As technology continues to advance, who knows what exciting developments we'll see in the world of in-situ leaching? One thing's for sure: the future of rare earth mining is looking brighter (and greener) than ever before.

FAQs

Is in-situ leaching safe for the environment?

While in-situ leaching generally has a smaller environmental footprint than traditional mining, it still carries some risks. Proper management and monitoring are essential to ensure groundwater protection and minimize environmental impact.

Can in-situ leaching be used for all rare earth deposits?

No, in-situ leaching is most effective for certain types of deposits, particularly those with porous rock formations. The geological characteristics of the deposit play a crucial role in determining the suitability of this method.

How does in-situ leaching compare to traditional mining in terms of cost?

In-situ leaching often has lower upfront costs due to reduced infrastructure requirements. However, the overall cost-effectiveness depends on various factors, including deposit characteristics and local regulations.

What are the main challenges facing in-situ leaching for rare earth elements?

Key challenges include developing efficient leaching solutions, ensuring environmental protection, navigating regulatory frameworks, and optimizing the process for different types of deposits.

How might in-situ leaching impact the global rare earth element market?

In-situ leaching has the potential to increase the supply of rare earth elements by making previously uneconomical deposits viable. This could help stabilize prices and reduce dependency on a limited number of suppliers.