Did you know that producing just one ton of rare earth elements can require a staggering 200 cubic meters of water? That's enough to fill an Olympic-sized swimming pool!

Imagine all that water filled with chemicals and solvents that environmentally impact the regions surrounding the mines. It's a more serious issue than most of us probably realize.

Let's dive in.

Table of Contents

What Exactly Is Rare Earth Mining Water Usage?

Rare earth mining water usage refers to the substantial amount of water required in the extraction and processing of rare earth elements (REEs). These elements, despite their name, are relatively abundant in the Earth's crust but are typically found in low concentrations, making their extraction resource-intensive.

- REEs include 17 metallic elements crucial for many modern technologies.

- They are used in electronics, renewable energy systems, and defense applications.

- The mining process involves extracting ore, separating REEs, and refining them.

The Mining Process

The extraction of rare earth elements typically follows these steps:

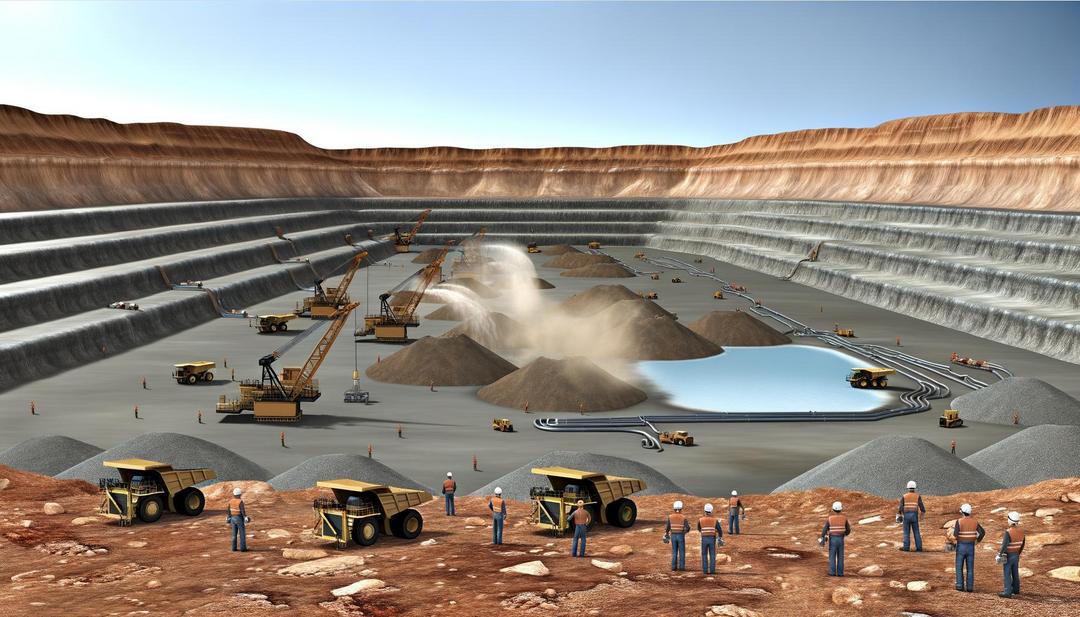

- Open-pit mining or underground mining to extract ore.

- Crushing and grinding of the ore.

- Beneficiation to concentrate the rare earth-bearing minerals.

- Chemical processing to separate individual REEs.

Water's Role in Rare Earth Extraction

Water plays a critical role throughout the rare earth mining process:

- It's used for dust suppression during mining and crushing.

- Large volumes are required for mineral separation and flotation.

- Chemical processing and leaching stages consume significant amounts of water.

- Water is needed for cooling equipment and other auxiliary processes.

Compared to other mining operations, rare earth mining tends to be more water-intensive due to the complex separation processes required to isolate these elements.

The Thirsty Giants: Top Water-Consuming Rare Earth Mining Processes

Certain rare earth mining processes are particularly water-intensive, contributing significantly to the industry's overall water footprint.

In-Situ Leaching

- Involves injecting a leaching solution directly into the ore body.

- Can consume up to 200 cubic meters of water per ton of rare earth oxides produced.

- Poses risks of groundwater contamination if not properly managed.

Flotation

- Uses large volumes of water to separate minerals based on their surface properties.

- Typically requires 400-500 liters of water per ton of ore processed.

- Generates significant amounts of wastewater that must be treated.

Solvent Extraction

- Involves multiple washing stages, each requiring substantial water inputs.

- Can consume up to 60 cubic meters of water per ton of rare earth oxides.

- Generates complex wastewater streams that are challenging to treat.

Case Study: Bayan Obo Mine, China

The Bayan Obo mine in Inner Mongolia, China, is the world's largest rare earth mine:

- It processes approximately 750,000 tons of rare earth concentrate annually.

- The mine's water consumption is estimated at 13 million cubic meters per year.

- This level of water usage has led to significant environmental concerns in the region.

Environmental Impact: When Water Meets Rare Earth

The intersection of water and rare earth mining can lead to severe environmental consequences.

Contamination Risks

- Mining wastewater often contains heavy metals, radioactive elements, and processing chemicals.

- Acid mine drainage can occur, leading to long-term water pollution.

- Tailings dam failures pose catastrophic risks to surrounding ecosystems.

Effects on Local Ecosystems

- Water pollution can devastate aquatic life and disrupt entire food chains.

- Excessive water extraction can lead to the drying up of rivers and wetlands.

- Soil contamination from wastewater can affect plant life and agricultural productivity.

Long-Term Consequences

- Overexploitation of water resources can lead to groundwater depletion.

- Contaminated aquifers may remain unusable for decades or even centuries.

- Ecosystem recovery can be slow and incomplete, even after mining operations cease.

Quenching the Thirst: Innovative Water Conservation Techniques

As awareness of water scarcity grows, the rare earth mining industry is exploring various water conservation techniques.

Water Recycling Technologies

- Membrane filtration systems can treat and recycle up to 90% of process water.

- Reverse osmosis plants are being implemented to purify and reuse wastewater.

- Closed-loop systems minimize freshwater intake and reduce overall water consumption.

Dry Processing Methods

- Dry magnetic separation reduces water usage in the beneficiation stage.

- Microwave heating techniques can potentially replace water-based extraction methods.

- Air classification systems offer water-free alternatives for particle separation.

Economic Benefits

- Reduced water consumption lowers operational costs.

- Improved water efficiency can lead to faster regulatory approvals.

- Water conservation technologies can extend the lifespan of mining operations in water-scarce regions.

Global Perspectives: Water Usage Regulations in Rare Earth Mining

Water usage in rare earth mining is subject to varying regulations across different countries and regions.

International Water Use Policies

- The International Council on Mining and Metals (ICMM) provides water stewardship guidelines (opens in a new tab).

- The United Nations' Sustainable Development Goals include targets for responsible water management (opens in a new tab).

Comparison of Regulations

- Australia: Strict water licensing and monitoring requirements.

- China: Implementing increasingly stringent environmental regulations.

- United States: Water rights and usage governed by both federal and state laws.

Challenges in Enforcement

- Limited resources for monitoring and enforcement in some jurisdictions.

- Complexity of tracking water usage in remote mining locations.

- Balancing economic development with environmental protection.

The Ripple Effect: Socio-Economic Impacts of Mining Water Usage

The water-intensive nature of rare earth mining can have far-reaching socio-economic consequences.

Competition for Water Resources

- Mining operations can divert water from agricultural and domestic uses.

- Water scarcity can lead to conflicts between mining companies and local communities.

- In arid regions, water allocation becomes a critical political issue.

Economic Trade-offs

- Job creation and economic growth from mining must be weighed against potential losses in agriculture.

- Water contamination can negatively impact tourism and recreation-based economies.

- Remediation costs for environmental damage can be substantial.

Public Health Concerns

- Contaminated drinking water sources can lead to various health issues.

- Bioaccumulation of heavy metals in the food chain poses long-term health risks.

- Dust from mining operations can cause respiratory problems in nearby communities.

Charting a Sustainable Course: The Future of Water Use in Rare Earth Mining

The future of water use in rare earth mining will likely be shaped by technological advancements and increasing environmental awareness.

Predictions for Future Water Demand

- Global demand for rare earth elements is expected to increase by 8-11% annually.

- Without significant technological improvements, water demand could rise proportionally.

- Climate change may exacerbate water scarcity in many mining regions.

Potential Game-Changing Technologies

- Bioleaching using microorganisms could reduce water and chemical use.

- Nanotechnology may enable more efficient separation processes.

- Artificial intelligence could optimize water usage across mining operations.

Circular Economy Principles

- Increased focus on recycling and urban mining of rare earth elements.

- Development of more easily recyclable products containing REEs.

- Exploration of alternative materials to reduce dependence on rare earth elements.

Conclusion

As we've seen, the water usage in rare earth mining is a complex issue with far-reaching implications. From environmental concerns to technological innovations, the industry stands at a crossroads. The challenge now lies in striking a balance between meeting the growing demand for rare earth elements and preserving our precious water resources. By embracing sustainable practices and cutting-edge technologies, we can pave the way for a more responsible and efficient mining future. The question is, are we ready to take the plunge?

FAQs

How much water does rare earth mining typically use?

Rare earth mining can use anywhere from 200 to 1,500 cubic meters of water per ton of rare earth oxides produced, depending on the specific mining and processing methods used.

What are the main environmental concerns associated with water use in rare earth mining?

The primary concerns include water pollution, depletion of local water resources, ecosystem disruption, and the potential for toxic elements to leach into groundwater.

Are there any rare earth mining methods that use less water?

Yes, some emerging technologies like dry processing and in-situ leaching aim to reduce water consumption significantly. However, these methods are still being developed and refined for widespread use.

How does rare earth mining water usage compare to other types of mining?

Rare earth mining generally uses more water than many other types of mining due to the complex separation processes required. However, exact comparisons vary depending on the specific minerals and extraction methods involved.

What can consumers do to support more sustainable water use in rare earth mining?

Consumers can support companies that prioritize sustainable mining practices, advocate for stricter environmental regulations, and consider recycling electronics to reduce the demand for newly mined rare earth elements.