For Beginners

Rare Earths 101

REEs might not be household names, but they lurk inside many devices and technologies we use daily and in strategic industries. Their unique magnetic, phosphorescent, and chemical properties make them indispensable in a broad range of applications.

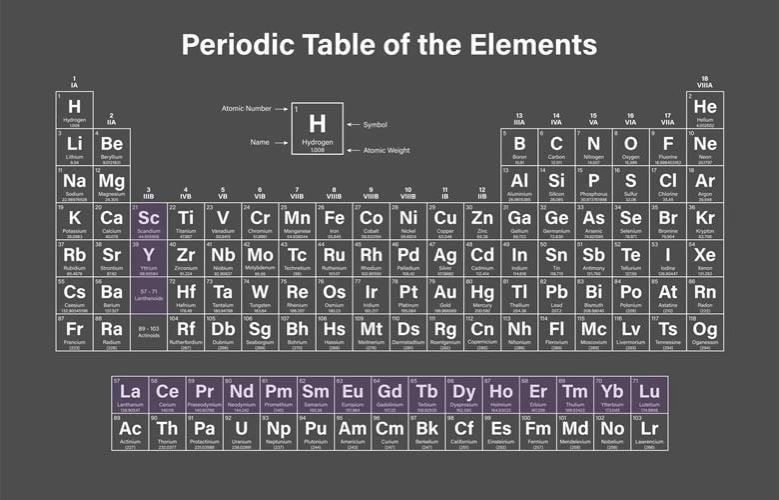

What Are Rare Earth Elements (REEs)?

Highlights

- 17 elements:

15 lanthanides + Scandium + Yttrium - Chemically similar, often found together in minerals

- Not geologically rare, but hard to process and separate

- Split into two groups:

Light REEs (La–Eu + Sc): more abundant

Heavy REEs (Gd–Lu + Y): rarer, more valuable - Key ores:

Bastnäsite

Monazite

Ion-adsorption clays - Extracted through mining + complex chemical separation

Key Uses of Rare Earth Elements

The following tables show the different rare earth elements used in each application, their approximate global volumes, and prices.

Table 1 – REE Applications and their usage by volume

| REE Application Amount (t/yr) | La | Ce | Pr | Nd | Pm | Sm | Eu | Gd | Tb | Dy | Ho | Er | Tm | Yb | Y | Sc |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Magnets | 500 | 200 | 9,000 | 50,000 | — | 300 | — | 100 | 300 | 1,500 | 50 | 50 | — | — | — | — |

| Batteries | 5,000 | 8,000 | 1,500 | 500 | — | — | 100 | — | — | — | — | — | 1 | 10 | 500 | 2 |

| Catalysts | 8,000 | 20,000 | — | — | — | 50 | — | 800 | 50 | 50 | 20 | 10 | 5 | — | — | — |

| Electronics | 200 | 200 | 100 | 500 | — | — | 10 | 50 | — | — | 30 | 100 | — | 1 | 100 | 3 |

| Medical | 300 | — | — | — | — | — | — | — | 100 | 300 | — | — | — | 20 | 50 | — |

| Defense | 50 | 100 | 100 | 1,000 | — | — | — | — | — | — | 5 | 20 | — | — | 3,000 | — |

| Optical | 500 | — | 50 | 500 | — | — | — | — | 50 | 100 | — | — | — | — | 500 | — |

| Ceramics | 1,500 | 100 | — | — | — | — | — | — | — | — | — | — | — | — | 100 | — |

| Glass | — | 18,000 | 100 | 100 | — | — | — | — | — | — | — | — | — | — | — | — |

| Sensors | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| Total Estimated (t/yr) | 16,050 | 46,600 | 10,850 | 52,600 | 0 | 350 | 110 | 950 | 500 | 1,950 | 105 | 180 | 6 | 31 | 4,250 | 5 |

Table 2 – Approx. values of each element

| REE Values | Approx Value (US$/t) |

|---|---|

| La | $1.75K |

| Ce | $1.5K |

| Pr | $47K |

| Nd | $60K |

| Pm | N/A |

| Sm | $4K |

| Eu | $21.5K |

| Gd | $40K |

| Tb | $275K |

| Dy | $260K |

| Ho | $57.5K |

| Er | $45K |

| Tm | $90K |

| Yb | $35K |

| Lu | $575K |

| Y | $6K |

| Sc | $4M |

Table 3 – Key REE to Focus on for investment

| Element | Main Scale Use | Importance |

|---|---|---|

| Nd | Magnets | Core to EVs/wind; high demand |

| Pr | Magnets | Blended with Nd in NdPr oxide |

| Dy | Magnets | High-temp stability; critical, rare |

| Tb | Magnets | Expensive, very limited supply |

Why Substitution of Rare Earth Elements is Difficult

If rare earths are so critical, why not simply replace them with other materials? The short answer: substituting rare earth elements is extremely challenging without sacrificing performance. These elements possess unique combinations of magnetic, electrical, and chemical properties that are hard to replicate with other elements. This is especially true in the case of high-performance magnets, which are among the most crucial rare-earth applications.

“Everyone would love a super-cheap magnet that outperforms neodymium but these “god-like” materials don’t currently exist – in fact, some say they never will. Still, every time the price of neodymium spikes, there’s a resurgence of interest in new magnets. In fact, I was shocked to learn at the Birmingham meeting just how many potential magnet materials are in the running. To me at least, it seems that the challenge isn’t in making new materials per se. What’s difficult is optimizing the material and the production process, which can literally take decades. As the Japanese scientist Masato Sagawa(opens in a new tab) – the inventor of neodymium magnets – pointed out in the opening plenary at REPM(opens in a new tab), it has taken 40 years of heroic effort for these materials to reach their current BHmax, which is about 90% of its theoretical maximum value, and to achieve high coercivity and high performance.”

Highlights

- Unique properties:

- Strong Magnetism

- Heat Resistance

- Alternatives (e.g., ferrite, induction motors) are heavier, less efficient

- Dy/Tb critical for high-temp magnet performance

- Substitution = performance loss or higher cost

- No comparable substitutes for NdFeB magnets – Do not believe the hype, take note of the quote from the inventor of the neodymium magnet.

Global Market & Geopolitics

China’s Rare Earth Monopoly and Geopolitical Leverage

China’s dominance in the rare earth market is the result of decades of strategic investment, low-cost production, and a willingness to absorb environmental damage. Since the 1980s, China has captured the majority of global rare earth mining, processing, and magnet manufacturing—accounting today for around 70% of mining and over 85% of refining. Even ore mined in the U.S. or Australia is often shipped to China for processing. This centralization creates serious supply chain vulnerabilities. In 2010, China halted rare earth exports to Japan during a maritime dispute, triggering global panic and price spikes. More recently, China introduced export controls on heavy rare earths (HREEs) like dysprosium and terbium, further underscoring its grip on high-tech supply chains and willingness to use REEs as a geopolitical tool. For many nations, especially in the West, this dependence has become a strategic liability.

Global Push to Diversify and Growing Demand Pressures

In response, the U.S., EU, Japan, and others are racing to diversify supply and build refining capabilities. Projects like MP Materials’ Mountain Pass mine and Lynas Rare Earths’ Malaysian separation plant are key milestones. New processing plants are underway in the U.S. and Europe, with government funding accelerating progress. However, breaking China’s near-monopoly won’t happen overnight—especially in refining and magnet production, where China maintains an overwhelming lead. Meanwhile, demand is booming, particularly for NdFeB magnets used in electric vehicles, wind turbines, and military tech. Light REEs like cerium are abundant and often oversupplied, but key magnet metals face tight supply and pricing volatility. For investors and policymakers alike, the rare earth sector presents both strategic opportunity and risk—where understanding geopolitical currents is just as important as tracking new mining ventures.

Highlights

China controls the global rare earth market:

- 70% of mining, 85% of refining, 90% of magnet production

- Key historical event: 2010 export halt to Japan → global panic and massive price increases

- Most HREEs sourced from China/Myanmar

- Strategic material: used as a geopolitical tool by China

Western response to China’s domination:

- Ex-China market starting to form, but in its early days

- Global investing in non-China supply chains

- Examples: Lynas & Arafura (Australia/Malaysia), MP Materials (U.S.)

- U.S. DoD funding REE projects (e.g., Texas separation plant)

- Critical Minerals Acts, trade alliances forming

Investing In Rare Earth Elements

Ways to Invest in Rare Earths and What to Watch

Investing in rare earth elements isn’t as simple as buying a commodity like gold or oil. There are no public spot markets for rare earth prices, so most exposure comes from owning shares in mining, refining, or manufacturing companies. Major players include miners like MP Materials and Lynas Rare Earths, processing firms like Neo Performance Materials, and tech manufacturers that use rare earths in magnets or electronics. Some ETFs like REMX or CRIT offer diversified exposure. However, most rare earth companies are small, and many are still in the development phase, making them speculative bets. Key value drivers include supply-demand dynamics (especially for magnet metals like Nd, Pr, Dy, Tb), government support for non-China projects, ESG factors, and a company’s ability to execute—many projects take 5–10 years and require significant capital. Due diligence on company finances, partnerships, and technical progress is essential.

Risks, Pitfalls, and Strategic Opportunities

The rare earth market is opaque and volatile—prices are often driven by geopolitical moves, not just fundamentals. China still dominates processing and refining, so many Western producers remain reliant on Chinese buyers or facilities. Trade tensions or export restrictions can sharply impact supply and prices, sometimes creating investor hype or fear. Other risks include technical challenges in processing, limited liquidity in rare earth stocks, and ESG scrutiny that can delay or derail projects. Investors should be wary of overhyped headlines and understand that a great ore deposit doesn’t always lead to a successful mine. That said, rare earths offer diversification in a clean energy-focused portfolio. With surging demand from EVs, wind power, and defense, long-term prospects are strong for companies that can navigate these risks and deliver critical materials to global markets.

Highlights

Types of Companies/Equities:

- Miners: MP Materials, Lynas, juniors (e.g., Arafura, Iluka)

- Refer to the Data Tools section of our website for a ranking of all the NdPr Projects/Deposits globally.

- Refiners: Neo Performance, Solvay

- Magnet Makers: Hitachi Metals, VAC, Shin-Etsu

- ETFs: REMX (VanEck), CRIT (Optica)

NOTE – the above is just a quick snapshot, there are many more in each category, and REEx will be providing our analysis on each category.

What to Watch:

- Supply/demand outlook for NdPr, Dy, Tb

- Project stage (many are pre-production)

- Mineralogy (how cost effective is it to mine and process)

- ESG concerns (waste, radiation)

- Off-take agreements

- Government backing

- Processing independence from China

- Geographic location of deposit

Common Pitfalls:

- Chasing hype (price spikes from news)

- Ignoring metallurgy/processing difficulty

- Assuming all REEs are equally valuable

- Overlooking China’s continued dominance

Rare Earth Future Trends

Emerging Trends Shaping the Rare Earth Future

The rare earth sector is evolving, with innovations and policy shifts reshaping its landscape. Recycling is gaining traction as a way to reduce reliance on mining, particularly as large-scale products like EV motors and wind turbines reach end of life. Startups and major players (like Solvay and Japanese firms) are investing in extracting rare earths from used magnets and industrial waste. Meanwhile, global regulations are tightening: the U.S. and EU are offering incentives for non-Chinese supply, while China is imposing stricter environmental rules and export controls, affecting global supply. New refining methods like membrane separation and green chemistry are in development, aiming to reduce costs and environmental impact. Projects are also exploring unconventional sources such as coal ash and red mud. While substitutes for rare earth magnets are being researched, widespread use is still years away—meaning demand for key elements like Nd, Pr, Dy, and Tb is expected to remain strong in the near term.

Strategic Outlook and Investor Implications

The rare earth industry is set to grow significantly, fueled by the electrification of transport, renewable energy expansion, and geopolitical urgency to diversify supply chains. By 2030, the market may see more regional players, but China will remain dominant due to its head start. Investors should monitor not just company performance, but also technological innovation, regulatory trends, and global trade policies—all of which impact pricing and project viability. Strategic partnerships, vertical integration (from mine to magnet), and ESG-friendly approaches could differentiate winners from overhyped prospects. Ultimately, rare earths are more than obscure metals—they are foundational to modern life and defense, making this a sector where understanding the science and politics is as critical as the balance sheet.

Highlights

- Recycling: wind turbines, EVs, e-waste (early stage)

- Innovation: membranes, bio-separation, ionic liquids

- Trade policies: U.S. IRA, EU CRMA, China export controls

- New sources: coal ash, red mud, deep sea (experimental)

- Substitution R&D: ongoing, but no viable large-scale replacement yet and could take decades.

Bottom Line For Investors:

- Rare earths (especially Nd, Pr, Dy, Tb) are vital to future tech

- China remains dominant, but diversification is happening

- High growth potential but high risk: due diligence essential

- Look for credible projects, government support, tech advantage