Rare Earth Element

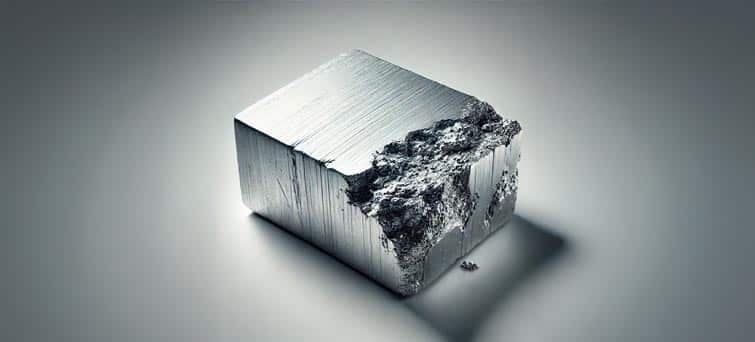

Dysprosium

Symbol: Dy

Ordinal Number: 66

Density: 8.54 g/cm³

Melting Point: 1,407°C (2,565°F)

Boiling Temperature: 2,567°C (4,653°F)

AI Representation

Introduction

Dysprosium: Enhancing Durability in High-Tech Applications

Dysprosium, one of the lesser-known rare earth elements, plays a pivotal role in advancing modern technology, especially under extreme conditions. Renowned for its strength and high melting point, Dysprosium’s unique properties make it indispensable in applications that require stability under high temperatures. Often alloyed with other rare earth metals, particularly Neodymium, it enhances magnetic resistance, making products more efficient and durable. From high-temperature magnets in electric vehicles to nuclear reactor control rods, Dysprosium’s contributions help improve safety, reliability, and efficiency in various critical sectors.

History/Discovery

The Discovery of Dysprosium: Uncovering the ‘Hard-to-Get’ Element

French chemist Paul Émile Lecoq de Boisbaudran discovered Dysprosium in 1886, following years of intensive research into rare earth metals. The name Dysprosium comes from the Greek word dysprositos, meaning “hard to get,” reflecting the challenges Lecoq faced in isolating it from its mineral form. Early uses of Dysprosium were minimal due to limited availability and complex extraction processes. However, as modern industries expanded, the demand for Dysprosium grew, primarily due to its thermal resistance and magnetic stability, making it indispensable for technologies that operate in extreme environments.

Characteristics

Dysprosium’s Defining Traits and Material Strength

Dysprosium is a relatively soft, silvery metal, but it stands out for its exceptional thermal resistance. It belongs to the heavy rare earth group and exhibits impressive stability at high temperatures, which is critical in applications that require durability and longevity. One of Dysprosium’s key characteristics is its ability to retain magnetic properties at elevated temperatures, which is rare among magnetic materials. This makes it invaluable in creating high-performance magnets that operate reliably in everything from electric motors to energy-efficient cooling systems. Dysprosium also has notable corrosion resistance, further enhancing its application in long-term infrastructure and equipment.

Popular Applications

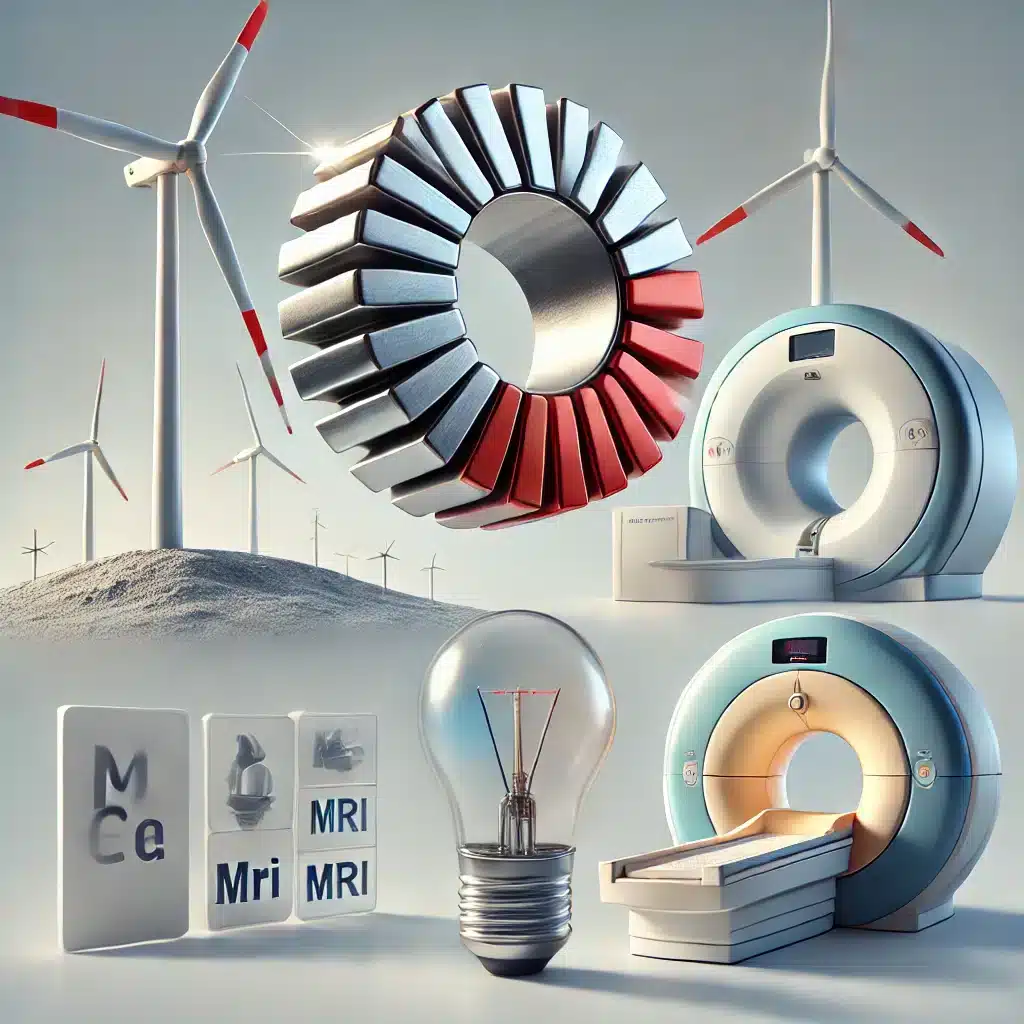

From Magnets to Reactors: How Dysprosium Advances Modern Tech

Dysprosium’s primary use lies in its ability to improve magnetic and thermal stability, which is essential in several high-tech applications. By adding Dysprosium to Neodymium magnets, engineers create “super magnets” that withstand extreme heat, making them suitable for electric vehicles, wind turbines, and other renewable energy technologies. Additionally, Dysprosium is critical in nuclear reactor safety as it absorbs neutrons efficiently, helping regulate and control nuclear reactions. As industries shift toward sustainable energy and high-performance technology, Dysprosium’s importance continues to grow.

List of Popular Applications

- Electric Vehicle Motors: Dysprosium is alloyed with Neodymium to create heat-resistant magnets in EV motors, ensuring performance under high stress.

- Wind Turbines: In wind turbines, Dysprosium-based magnets maintain magnetic strength even at high temperatures, enhancing energy efficiency.

- Nuclear Reactors: Dysprosium acts as a neutron absorber in control rods, aiding in the safe and stable operation of nuclear reactors.

- Advanced Electronics: High-performance electronics use Dysprosium to enhance thermal resistance, making components more reliable over time.

Where You Find Dysprosium in the World

Dysprosium Reserves: A Strategically Valuable Resource

Dysprosium is mainly extracted from heavy rare earth minerals found in limited locations worldwide, including China, the United States, and Australia. China holds the majority of Dysprosium reserves, dominating the global supply chain and positioning it strategically in international trade. The mining and processing of Dysprosium are complex and environmentally intensive, often resulting in considerable waste. Due to Dysprosium’s high demand and limited availability, researchers are exploring new methods to recycle this rare earth metal from discarded electronics and industrial equipment, aiming to mitigate environmental impacts and ensure a sustainable supply.

The Future of Dysprosium

Dysprosium’s Role in Sustainable Energy and Future Tech

As the world’s focus on sustainable energy intensifies, Dysprosium’s role in high-performance applications will continue to grow. Its ability to enhance the durability and efficiency of magnets, essential in electric vehicles and renewable energy infrastructure, makes it indispensable. Given Dysprosium’s scarcity, however, the challenge lies in maintaining a steady supply while minimizing environmental impacts. Advances in recycling technologies and synthetic alternatives are being researched to ensure Dysprosium’s availability, positioning it as a key player in green energy technology and the next generation of electronic innovations.