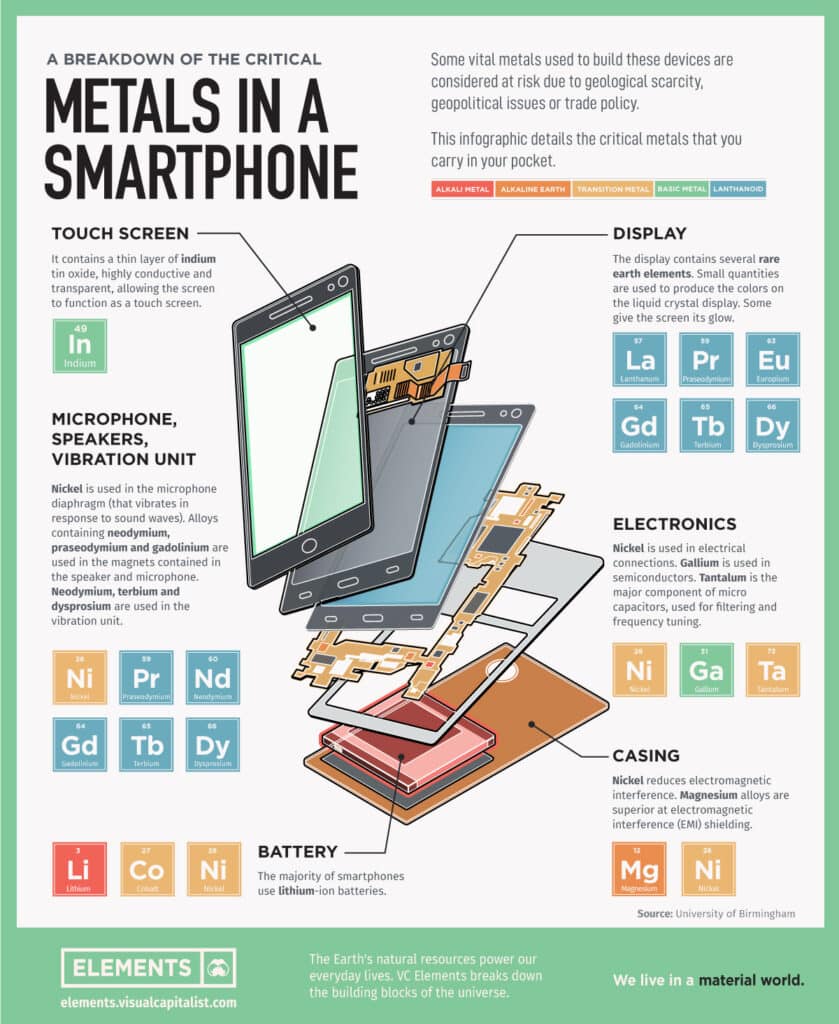

Did you know the average smartphone contains 16 of the 17 different rare earth elements? Now multiply that by millions of devices, add in electric vehicles, wind turbines, and advanced military systems, and you'll start to see why rare earths are as valuable as gold. The catch?

Over 70% of these critical elements are controlled by a single country—China. Welcome to a global supply chain dilemma that America must solve to secure its economy, national defense, and environmental goals.

In this article, we'll break down the key reasons why the U.S. desperately needs a resilient rare earth supply chain.

Spoiler alert: It's about more than just smartphones.

Table of Contents

What Is a Resilient Rare Earth Supply Chain—and Why Does the USA Need One?

Rare earth elements (REEs) might sound like something from a science fiction novel, but they're actually crucial components in many of the technologies we use every day. These 17 unique metallic elements play a critical role in everything from smartphones and electric vehicles to advanced military equipment and renewable energy technologies.

The United States currently faces a significant challenge in rare earth production. While global demand continues to skyrocket, China dominates the market, producing over 70% of the world's rare earth minerals. This creates a dangerous dependency that threatens national security, economic stability, and our ability to lead in green technologies.

Understanding the Strategic Importance

Supply chain resilience isn't just a buzzword—it's a critical national priority. Imagine a scenario where geopolitical tensions could cut off access to these essential minerals. The impact would be devastating, potentially crippling industries from technology and defense to renewable energy.

1. Mapping the USA's Rare Earth Supply Chain: Current Gaps and Challenges

The United States has limited rare earth mining capabilities. The Mountain Pass mine in California represents one of the few domestic production sites, but it's just a small piece of a much larger puzzle. Currently, the U.S. accounts for only 15% of global rare earth mining and lacks the infrastructure for comprehensive domestic processing.

The Processing Problem

The real challenge goes beyond mining. The U.S. struggles with critical supply chain processes like refining and separation. While raw materials might be available, the ability to transform these minerals into usable components remains severely limited.

2. Global Dynamics: How Geopolitics Shape Rare Earth Supply Chains

China's dominance in the rare earth market isn't just an economic issue—it's a strategic one. The 2010 dispute between China and Japan over rare earth exports demonstrated how quickly these critical minerals can become a geopolitical weapon.

Emerging Alternatives

Countries like Australia and Canada are emerging as potential alternatives, offering hope for a more diversified global rare earth market. These nations are actively developing their own rare earth industries, providing potential partnerships for the United States.

3. The National Security Threat: Rare Earths in Defense and Technology

Military systems depend critically on rare earth elements. The F-35 fighter jet, for instance, relies on rare earth magnets for crucial operational components. Any disruption in the supply chain could directly impact national defense capabilities.

Pentagon's Strategic Response

The U.S. Department of Defense is increasingly aware of these vulnerabilities. Strategic initiatives are being developed to secure critical mineral supply chains and reduce dependence on potential adversaries.

4. Lessons from Success: Models of Resilient Rare Earth Supply Chains

Australia's Lynas Corporation offers an inspiring model of supply chain diversification (opens in a new tab). By developing comprehensive processing capabilities and forming strategic international partnerships, they've demonstrated an effective approach to rare earth production.

International Collaboration

Partnerships through groups like the QUAD (opens in a new tab) (United States, India, Japan, Australia) present promising opportunities for creating more resilient and diversified rare earth supply networks.

5. Sustainability and Rare Earths: Can the U.S. Lead in Green Innovation?

Rare earth mining traditionally comes with significant environmental costs. However, the United States has an opportunity to lead in developing more sustainable extraction and recycling technologies.

The Circular Economy Approach

Innovative recycling programs, particularly those focusing on e-waste recovery, could transform the management of rare earth minerals. This approach would reduce environmental impact and create new economic opportunities.

6. Building a Path Forward: Strategies to Strengthen the U.S. Rare Earth Supply Chain

Government initiatives like the Defense Production Act (opens in a new tab) are critical to domestic rare earth projects. Private sector innovation, coupled with strategic government funding, offers a promising path forward.

Collaboration is Key

Partnerships between government agencies, academic institutions, and private industry will be crucial in developing comprehensive solutions for rare earth supply chain challenges.

Conclusion

Securing a resilient rare earth supply chain in the U.S. is more than a strategic goal; it's a matter of national survival in a rapidly evolving world.

From safeguarding national security to driving the green energy revolution, rare earths are the linchpin that connects innovation, sustainability, and economic growth.

While the challenges are significant, so too are the opportunities for the U.S. to lead in this critical domain.

FAQs

What are rare earth elements, and why are they important?

Rare earth elements (REEs) consist of 17 metals vital for high-tech applications such as smartphones, renewable energy technologies, and military systems. They are critical to modern innovation and national security.

What is the current state of the rare earth supply chain in the USA?

The U.S. produces around 15% of global rare earths, primarily through mining at Mountain Pass, California. However, the country relies heavily on foreign nations, particularly China, for refining and manufacturing.

Why is China dominant in the rare earth market?

China's dominance stems from decades of investment in mining, refining, and processing infrastructure. It controls more than 70% of global rare earth supply and has strategically secured its role in the value chain.

How can the U.S. reduce reliance on foreign rare earth supply chains?

The U.S. can focus on diversifying its sources, investing in domestic refining capabilities, fostering recycling programs, and collaborating with allied nations for supply chain resilience.

Are rare earths environmentally sustainable?

Currently, rare earth mining has significant environmental impacts, but new technologies and recycling efforts can reduce this footprint. A shift toward sustainable practices is critical for future supply chains.